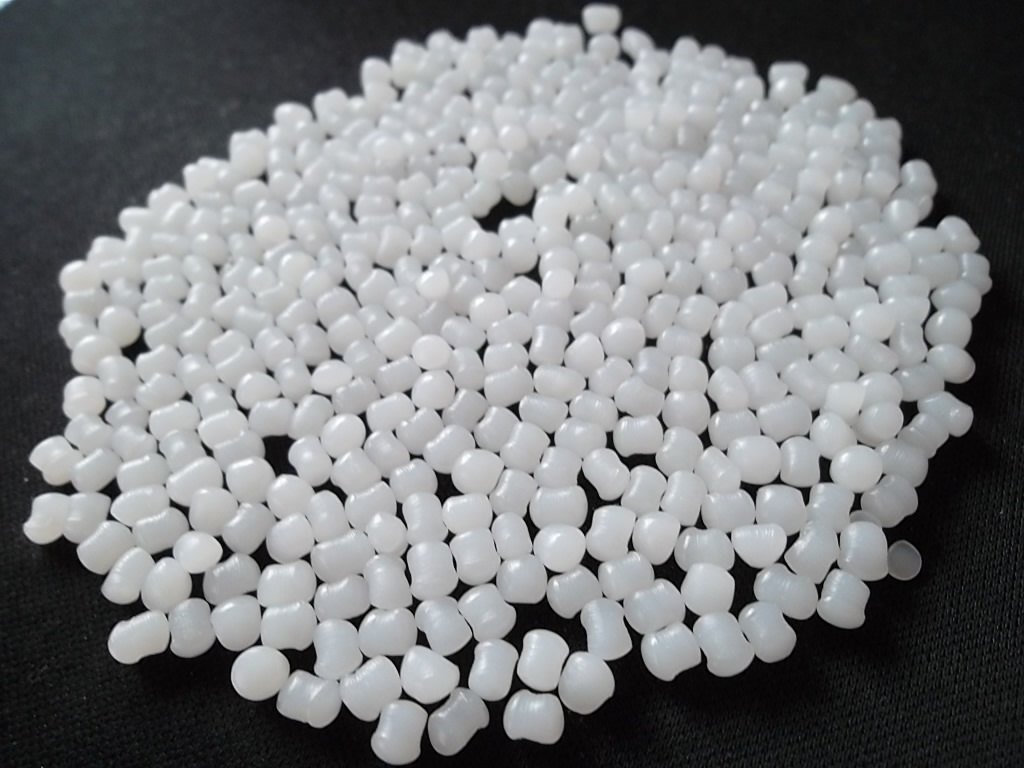

SAT India offers comprehensive solutions for the plastic and polymer industries, designed to optimize material handling from raw material receipt to finished product packaging. Our systems include a combination of mechanical and pneumatic conveying for materials like polymers, resins, and additives, precise blending of different polymer grades, and pneumatic conveying of finished products to storage silos. We also provide de-dusting solutions to remove fines and streamers before packaging, along with automated bagging and pelletizing systems. These solutions ensure efficient, safe, and high-quality production processes, meeting the growing demands of the plastic and polymer sectors.

Weighing & Packaging Systems: Integrated systems that weigh, fill, and seal bags or containers, ensuring precise quantities and reducing waste.

These solutions are tailored to the growing demands in the plastic and polymer industries, where efficiency, quality, and contamination control are paramount. By implementing these systems, companies can ensure consistent product quality, meet industry demands, and optimize their production processes.

Land Survey No. 97, Paiki Lamdapura, Tal. Savli, Dist - Vadodara - 391775

Copyright © 2024. All rights reserved. Design By Techno Mantra